-

Automation and digital product integration providerFV5-U3 EtherCAT SERVO FV5-U3 PULSE SERVO FV5L-U3 EtherCAT SERVO FV5L-U3 PULSE SERVO FD5-U LOW VOLTAGE EtherCAT SERVO FD5-U LOW VOLTAGE PULSE SERVO FD5-R LOW VOLTAGE EtherCAT SERVO FD5-R LOW VOLTAGE PULSE SERVO23BIT MULTITURN SERVO MOTOR-40 FLANGE 23BIT MULTITURN SERVO MOTOR-60 FLANGE 23BIT MULTITURN SERVO MOTOR-80 FLANGE 23BIT MULTITURN SERVO MOTOR-110 FLANGE 23BIT MULTITURN SERVO MOTOR-130 FLANGE 23BIT MULTITURN SERVO MOTOR-180 FLANGE LOW VOLTAGE MOTOR-40 FLANGE LOW VOLTAGE MOTOR-60 FLANGE

-

Automation and digital product integration provider

-

Automation and digital product integration provider

High-speed Arranging Machine

Background The high-speed arranging machine is a critical piece of equipment in the photovoltaic industry. It is specifically designed for the production of solar panels, and its main function is to rapidly and accurately arrange soldered solar cells onto a substrate layer according to a specific layout.

The high-speed arranging machine is a critical piece of equipment in the photovoltaic industry. It is specifically designed for the production of solar panels, and its main function is to rapidly and accurately arrange soldered solar cells onto a substrate layer according to a specific layout.

The Challenge

The high-speed arranging machine requires excellent pendulum accuracy and has a high utilization rate so the customer was looking for a robust, high performance solution that delivered the required speed and yield rate.

The Benefits

Combining technology solutions from FLEXEMATiC enhanced the machine’s performance, with a pendulum accuracy of battery strings of ≤0.2mm, yield rate of ≥99.5% and equipment utilization rate of ≥99.5%. In addition to the significant performance improvements, the solution also provided the customer with a 10% cost saving, while the IoT HMI provided remote maintenance capabilities and real-time monitoring of equipment status. Having a single source for all touchscreens, servos and linear motors facilitated ease of maintenance and modification for the customer.

The solution

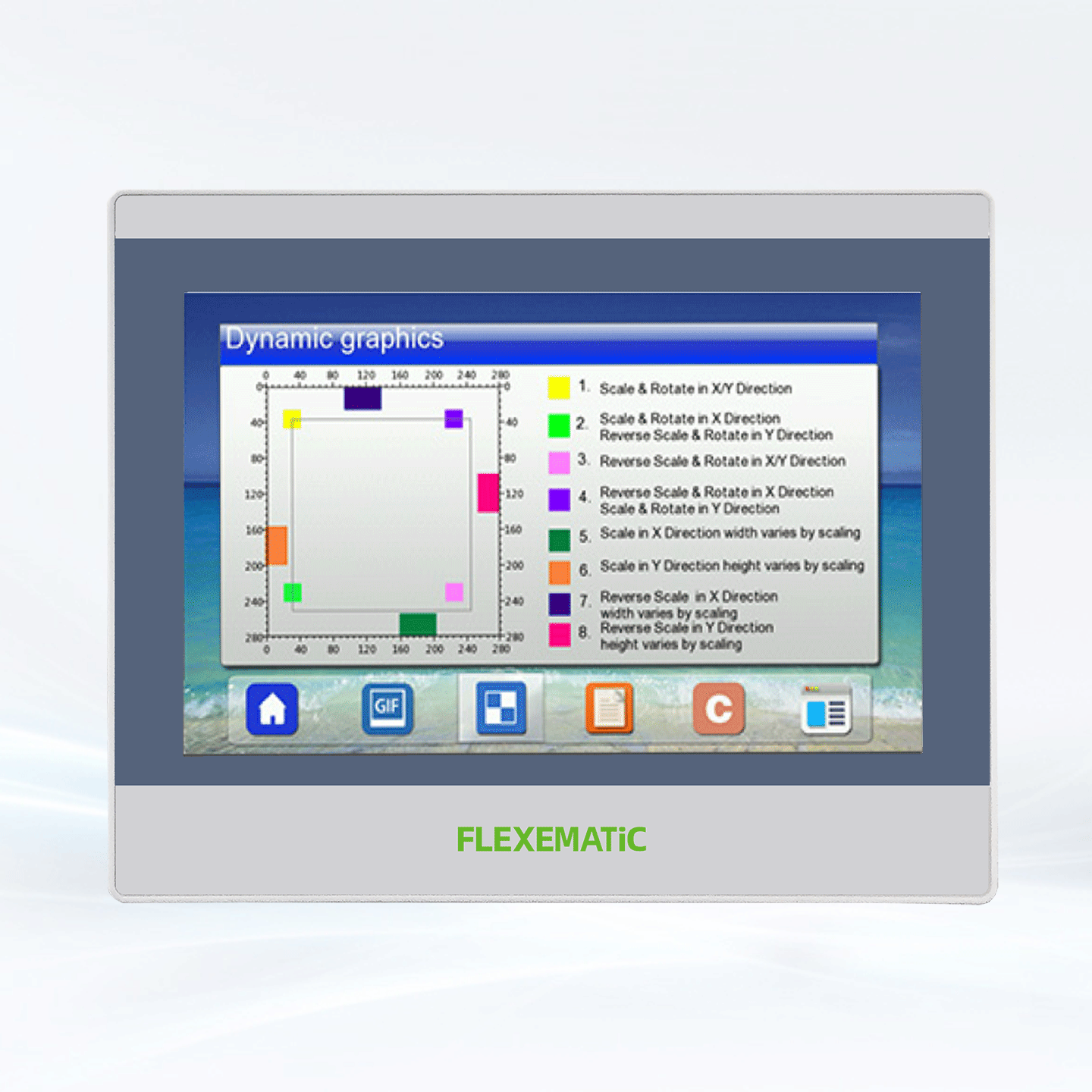

The chosen solution combines a FLEXEMATiC FL8-E16-D controller with the FR-D1600 and FR-D0016N expansion modules. Comprising a total of 21 axes of 400W and 750W bus servos and using the FLEXEMATiC FV5-U3 series rotary servos, the solution also features a FLEXEMATiC FS610R IoT screen paired with FWay2 for easy access to data via the cloud.

recommend products

Related Downloads

High-speed Arranging Machine

Phone: +1 959-263-9093

Email:info@flexematic.com

Add: 570 Hayden Station Rd, Unit D, Windsor, CT 06095

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.