-

Automation and digital product integration providerFV5-U3 EtherCAT SERVO FV5-U3 PULSE SERVO FV5L-U3 EtherCAT SERVO FV5L-U3 PULSE SERVO FD5-U LOW VOLTAGE EtherCAT SERVO FD5-U LOW VOLTAGE PULSE SERVO FD5-R LOW VOLTAGE EtherCAT SERVO FD5-R LOW VOLTAGE PULSE SERVO23BIT MULTITURN SERVO MOTOR-40 FLANGE 23BIT MULTITURN SERVO MOTOR-60 FLANGE 23BIT MULTITURN SERVO MOTOR-80 FLANGE 23BIT MULTITURN SERVO MOTOR-110 FLANGE 23BIT MULTITURN SERVO MOTOR-130 FLANGE 23BIT MULTITURN SERVO MOTOR-180 FLANGE LOW VOLTAGE MOTOR-40 FLANGE LOW VOLTAGE MOTOR-60 FLANGE

-

Automation and digital product integration provider

-

Automation and digital product integration provider

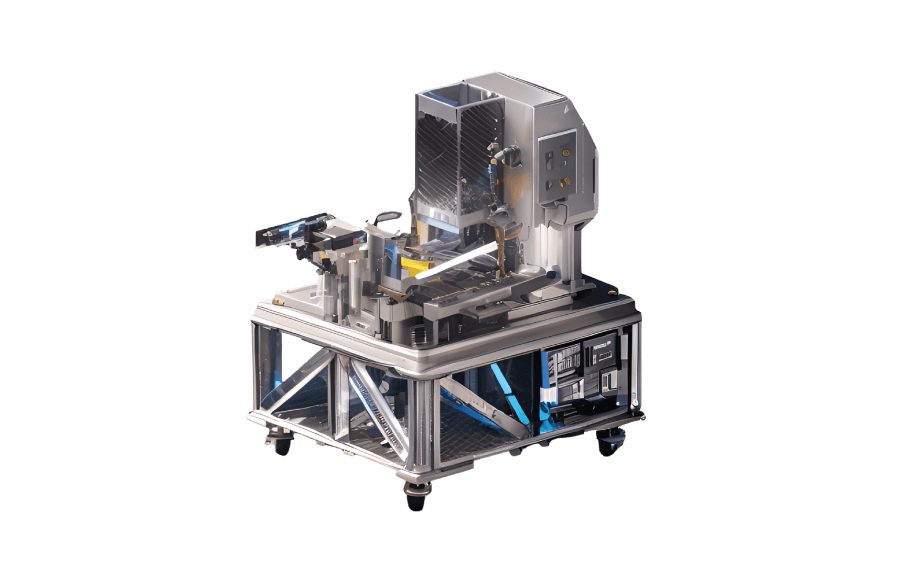

LED Die Bonder

Background The customer is an OEM with an LED die bonder used in the semiconductor industry. The machine in question is an automated device that transfers LED chips from wafer trays onto printed circuit boards (PCBs). The equipment carries out automatic die bonding of LED chips and includes sensors to detect any defects in the chips.

The customer is an OEM with an LED die bonder used in the semiconductor industry. The machine in question is an automated device that transfers LED chips from wafer trays onto printed circuit boards (PCBs). The equipment carries out automatic die bonding of LED chips and includes sensors to detect any defects in the chips.

The Challenge

The LED die bonder operates at very rapid speeds and requires acute positioning accuracy for each chip. The OEM was looking for a motion control solution capable of meeting the high reliability, speed and precision requirements of the application, including operational efficiency of 90-100k units per hour, single action time of ≤70 m/s, and endpoint Positioning Accuracy of ≤6 μm.

The Benefits

FLEXEMATiC delivered a range of benefits to the customer, including improving the end-point positioning accuracy of the swing arm to 5.2 μm. The instruction takes 46 ms and the setting takes 11 ms, with a total time of 57 ms, without overshooting or jitters. Additionally, the solution delivers an efficiency improvement, achieving an efficiency of 45 K/H for single-side feeding and 90 K/H for double-side feeding. As well as enhancing equipment performance, FLEXEMATiC also provides cost advantages compared with competitors.

The Solution

The solution utilizes an industrial computer with motion control cards, paired with a 4 kW rotary hollow servo motor, along with FV5-U series rotary servo drives. The current for the DDL and voice coil motors ranges from 3 A to 6 A, complemented by FV5-U series direct-drive servo drives.

recommend products

Related Downloads

LED Die Bonder

Phone: +1 959-263-9093

Email:info@flexematic.com

Add: 570 Hayden Station Rd, Unit D, Windsor, CT 06095

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.