-

Automation and digital product integration providerFV5-U3 EtherCAT SERVO FV5-U3 PULSE SERVO FV5L-U3 EtherCAT SERVO FV5L-U3 PULSE SERVO FD5-U LOW VOLTAGE EtherCAT SERVO FD5-U LOW VOLTAGE PULSE SERVO FD5-R LOW VOLTAGE EtherCAT SERVO FD5-R LOW VOLTAGE PULSE SERVO23BIT MULTITURN SERVO MOTOR-40 FLANGE 23BIT MULTITURN SERVO MOTOR-60 FLANGE 23BIT MULTITURN SERVO MOTOR-80 FLANGE 23BIT MULTITURN SERVO MOTOR-110 FLANGE 23BIT MULTITURN SERVO MOTOR-130 FLANGE 23BIT MULTITURN SERVO MOTOR-180 FLANGE LOW VOLTAGE MOTOR-40 FLANGE LOW VOLTAGE MOTOR-60 FLANGE

-

Automation and digital product integration provider

-

Automation and digital product integration provider

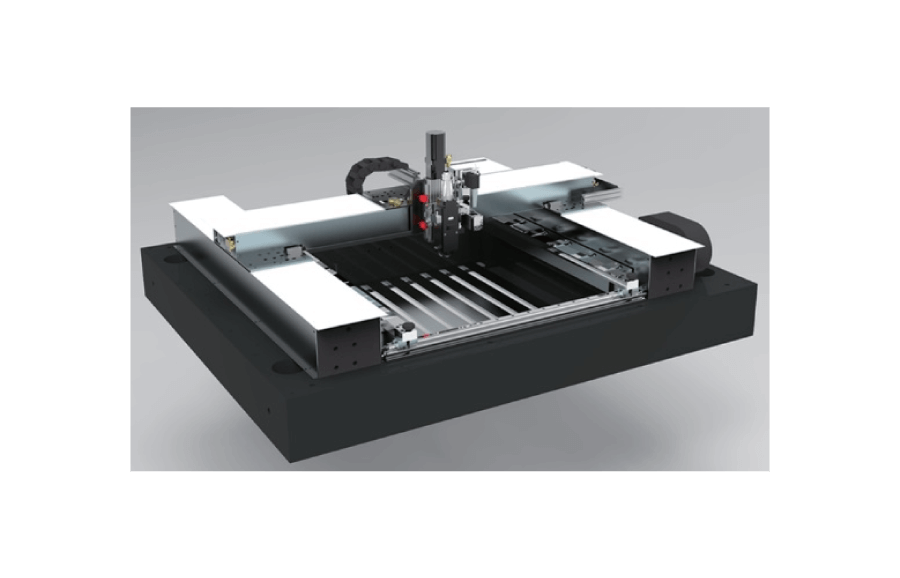

Precision Laser Cutting Machine

Background The customer is an OEM with a small-power laser cutting machine that employs laser technology for precision cutting various metals. Used primarily in the machine tool industry, the device relies on efficiency and accuracy to deliver high quality products that meet the high standards required by modern manufacturers for precision machining.

The customer is an OEM with a small-power laser cutting machine that employs laser technology for precision cutting various metals. Used primarily in the machine tool industry, the device relies on efficiency and accuracy to deliver high quality products that meet the high standards required by modern manufacturers for precision machining.

The Challenge

Because laser cutting machines require high levels of accuracy, the customer was looking for a high value motion control solution that enhanced performance, reduced error rates and delivered high precision.

The Benefits

The chosen solution from FLEXEMATiC delivers enhanced equipment performance through more precise servo control, alongside cost advantages compared with competitors’ solutions. FLEXEMATiC solution delivers absolute positioning accuracy of ≤ 2 microns, repeatability of ≤ ±0.5 microns and operating speed of 1m/s in both X and Y directions.

FLEXEMATiC was able to provide a follow-up error rate of ≤5 µm. The Parkson system’s command cutting trajectory has a minimum diameter circle of 0.2 mm, with errors within one thread throughout the process. The instantaneous speed of the lifting Z-axis can reach 5000 rpm.

The Solution

The solution utilizes an industrial computer with motion control cards. A FLEXEMATiC FV5-U3-NA3R0 servo drive with a 400W output power is employed for the XY axis, paired with a DDL motor. For the Z axis, FV5-U3-NA1R6 drive is used to power a rotary motor with a lead screw.

recommend products

Related Downloads

Presicion Laster Cutting Machine

Phone: +1 959-263-9093

Email:info@flexematic.com

Add: 570 Hayden Station Rd, Unit D, Windsor, CT 06095

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.